Raw cow’s milk, salt and rennet. These three ingredients, together with time and human know-how, are enough to make Parmigiano Reggiano, the cheese from Emilia-Romagna whose recipe has been passed down from father to son for centuries in all the dairies of the region. A pure artisanal delight with a sharp, fruity taste that can reach financial heights when sold.

A TRADITIONAL AND GENERATIONAL KNOW-HOW

At dawn, in the Caseificio Ugolotti, nestled in the Italian countryside not far from Parma, workers dressed in white aprons are busy processing the skimmed milk from the evening milking and the fresh milk from the early morning milking. We have to work fast! Time and people are essential factors in the production of Parmigiano Reggiano. In this family-run dairy dating back to 1930, the workers succeed one another from father to son. To embrace this hard and physical job at an early age, passion is a sine qua non condition.

This unpressed cooked cheese, holder of a Protected Designation of Origin (DOP in Italian), was born more than 1200 years ago in the Benedictine monasteries of the production area.

GUARANTEED TRACEABILITY THROUGHOUT THE PROCESS

Even today, the cheeses that come out of the 335 workshops are all made according to precise specifications established by the Consorcio del Formagiano Parmigiano Reggiano, the control body created in 1934. The milk production is divided into three batches corresponding to three periods in the year: 1st batch from January to April, 2nd batch from May to August, 3rd batch from September to December.

« Throughout the process, traceability is guaranteed, » explains a Consorcio manager. Because for the final product to be of good quality, rigor is required. « In 2018, more than three million eight hundred thousand wheels left the workshops » she says. Knowing that a wheel of cheese can reach 400€… It is therefore important to pay attention to the elaboration of this real treasure hidden in the cave of maturing.

FOUR COWS WITH CASEIN-RICH MILK

It all begins in the fields of the Emilia-Romagna region. The production area covers the provinces of Parma, Reggio Emilia, Modena, part of Mantua on the right bank of the Po River, and part of Bologna on the left bank of the Reno River. The cows that produce Parmesan milk come from four dairy breeds: the Modenese (a light-colored cow also known as Bianca val Padana), the Bruna Italiana (a Braunvieh imported from Switzerland), the Frisona (a Holstein imported from the Netherlands and the United States) and the Reggiana (probably the mother breed of the cheese). The milk of the latter is richer in proteins, especially casein, than that of the others. The quality of their milk is undoubtedly due to the fact that they are fed « mainly with hay, at least 75% of the dry matter of which comes from the Parmigiano Reggiano production area ». The hay must be of excellent quality, with a beautiful green color. Silage, fermented feed, animal meal, preservatives and additives during the production process are strictly forbidden.

MILK, GESTURES AND NATURAL RENNET

At the dairy, 1100 liters of milk are heated to 35°C with steam in copper cauldrons shaped like truncated cones. « These cauldrons are used only once a day, » says Attilio, the master cheese maker. « The natural rennet of suckling calves is added to the heated milk, » he says. During seven minutes, the milk rests and coagulates slowly. When the material has reached the right consistency, the cheesemaker will cut it with a spino and then dehydrate it at high temperature (56°C). The cheesemaker dips his hand in this milky bath to judge the size and quality of the cheese grains. The grains gradually agglomerate at the bottom of the vat. With dexterity, two cheesemakers will then recover this compact mass in a cloth, cut it, put it in two other linen cloths and finally hang them to make them lose all their water.

A VERY STRICT SPECIFICATION

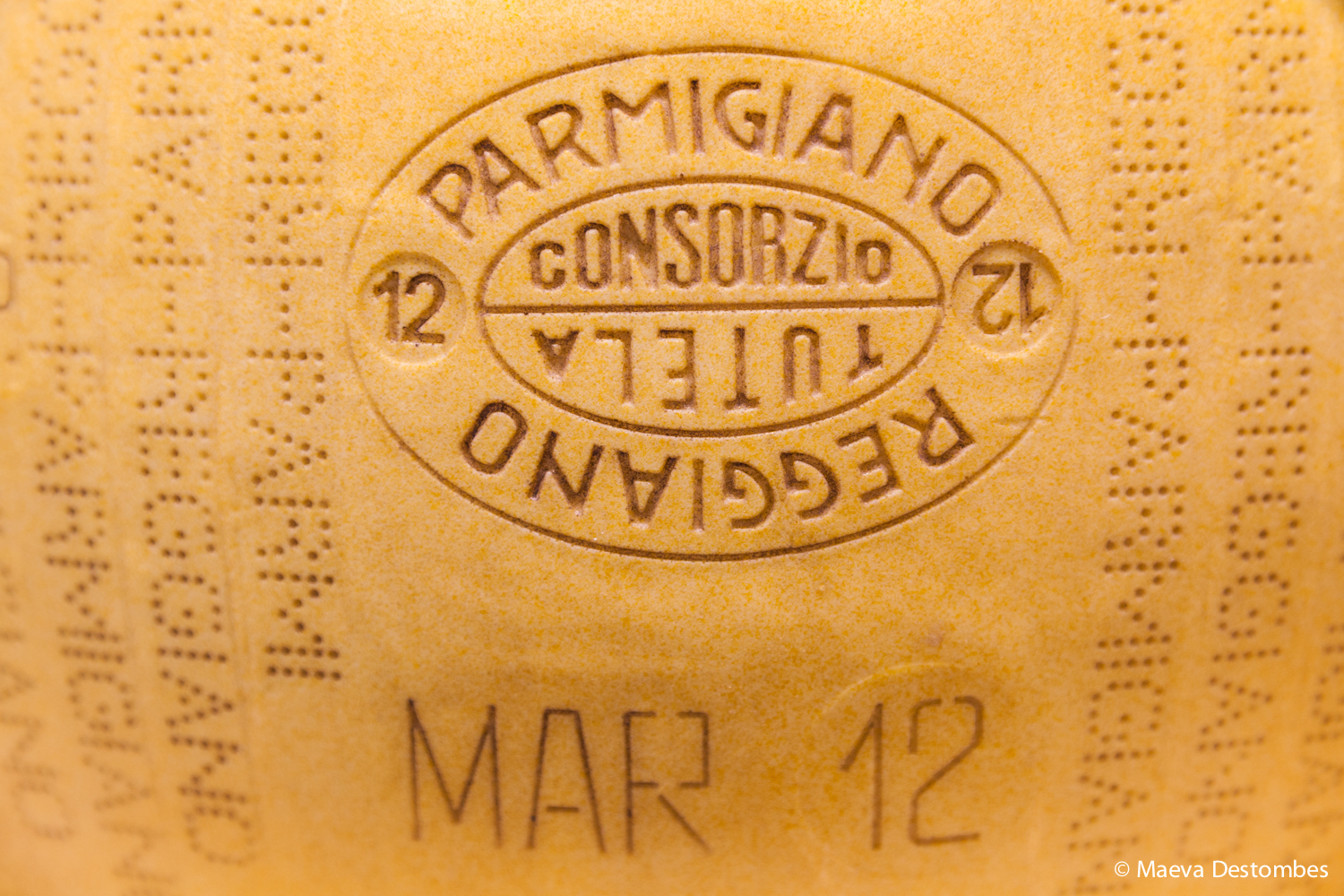

The curd balls are then placed in plastic vices (fascera) and flattened with heavy wooden discs for two to three days. The Parmesan cheeses are then surrounded by a dotted marking matrix – bearing the dairy’s registration number, the year and month of production – and encircled by a perforated metal mold. A few days later, they are immersed for at least 12 days, according to the specifications, in a salt solution at 18°C, the melting point of milk. But most manufacturers leave them between 20 and 25 days. From this salt bath, the Parmesan cheese will draw most of its flavor and its granular and salty texture. For a minimum of 12 months, and up to 48 months for exceptional Parmesan cheeses, the cheeses are matured in huge warehouses where the temperature is maintained at 18-20°C.

MATURING, THE FINAL TOUCH TO AN EXCEPTIONAL PRODUCT

« Some Parmesan cheeses will be matured for up to 100 months, » says the Consorcio’s manager. A record for these wheels that will be sold at a golden price. Over time, each « wheel » weighs at least 30kg, but often 45kg, and acquires its beautiful golden straw color and powerful aroma, both pungent and fruity. Inside, the paste is finely grained and breaks into flakes when cut. The color of the rind is the distinctive sign that allows experts to know the age without looking at the certification mark. The latter is affixed to wheels that pass inspection. Other tests, such as sound tests using a hammer, are carried out on the wheels. Two categories of Parmesan cheese are produced. Parmigiano Reggiano (aged 24 months) and Parmigiano Reggiano Mezzano (aged 12 months) to which are added two more rigorous qualities: Extra or Export. A good Parmesan cheese can be recognized by its strong smell. It leaves your mouth and hands clean. The words of an expert!